Automotive Industry

CNC machining plays a significant role in the auto manufacturing industry. The increased production speeds, tight tolerances, and consistent quality made possible by CNC machining technology has transformed automotive manufacturing. CNC machining is suitable for use with many kinds of materials, and product designers rely on CNC for rapid prototyping and production of an extensive range of essential automotive parts.

Efficient Parts Design and Rapid CNC Machining

CNC machining is not only one of the fastest ways to manufacture prototypes, but CNC automated machining can greatly increase production speeds and reduce manufacturing costs. Improvements in design, robotics, and manufacturing processes have all led to significant increases in the efficiency of automotive machining. CNC technology has also made possible improvements in vehicle design and performance.

Higher Precision and Accuracy

In the automotive industry, tolerances are very critical, so the precision of the machining tools used is important. Every item produced must be identical. Besides maintaining high precision, CNC software will also determine if a machining parameter has not been set properly and make needed corrections. By using CNC automation, the chance of human error is greatly reduced, assuring that all parts will be machined exactly to product specifications.

FENG CHING Quality Assurance

FENG CHING Company was founded in 1995, processing traditional aluminum alloys parts for Taiwan’s bicycles and motor cycle industries. In 2001, FENG CHING transitioned to CNC precision machining for its milling, drilling, turning, and cutting operations.

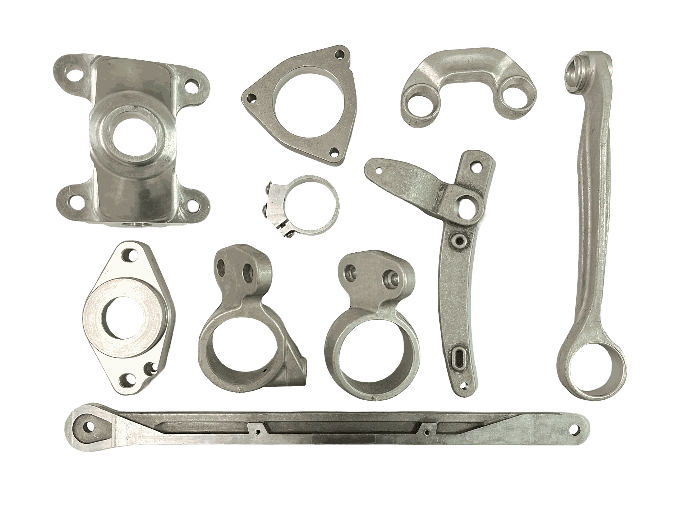

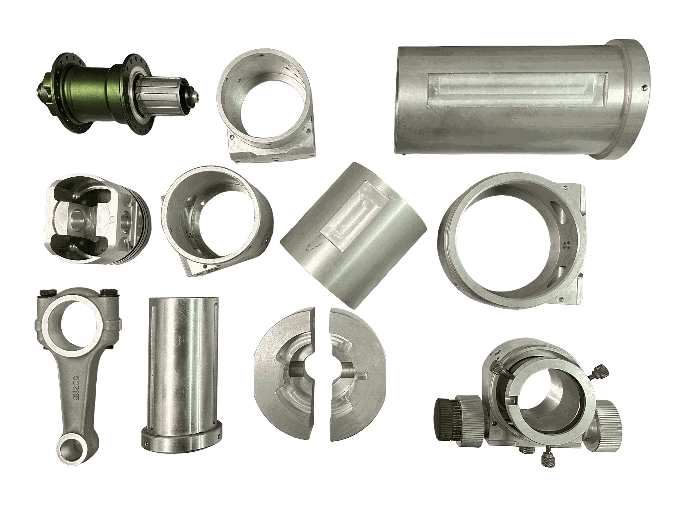

In 2011, FENG CHING again upgraded all the facilities, and began manufacturing automobile parts, including aluminum alloy chassis parts such as automotive triangles, shock absorbers, connecting rods, control arms, balance shafts, and bushings. We also manufactured engine parts like cylinder heads, connecting rods, and crankshafts, as well as various other components related to suspension systems, brake systems, and off-road vehicle fairlead.

We presently manufacture OEM automotive parts used in world-class racing cars, automobiles, heavy locomotives, bicycles, hand tools and other related industries. At present, FENG CHING has 60 CNC machines running 24 hours a day, and our CMM testing procedures assure that quality is maintained to the highest of standards.

Our Partners

FENG CHING’s expansion over the past two decades has always been about providing you, our customer, with the best possible CNC manufacturing solutions. We presently provide OEM and ODM manufacturing of high-quality custom car parts for international brand-name automotive manufacturers, manufacturing according to International Automotive Task Force (IATF) standards. If you’re searching for a reliable partner to reduce your manufacturing costs and increase productivity we are here to help.