Bicycle Industry

For the past thirty years, Taiwan has been the global center for the manufacturing of high-end bicycles. Integrating CNC manufacturing capabilities with bicycle manufacturing has given invaluable support to the bicycle manufacturing industry.

Increasing Efficiency and Cutting Costs

The bicycle industry is extremely competitive and therefore rapid production speeds, and consistent quality are essential. The versatility of CNC machining makes it possible to design new parts, and efficiently manufacture these new designs, while maintaining consistent quality.

Because CNC can be used for producing nearly all parts in a bicycle, once production is set up, large volumes of high-quality parts can be produced. While initial investment for CNC is higher than traditional machining, the high-volume production capability of CNC makes it highly worth the investment.

High Quality Bicycle Component

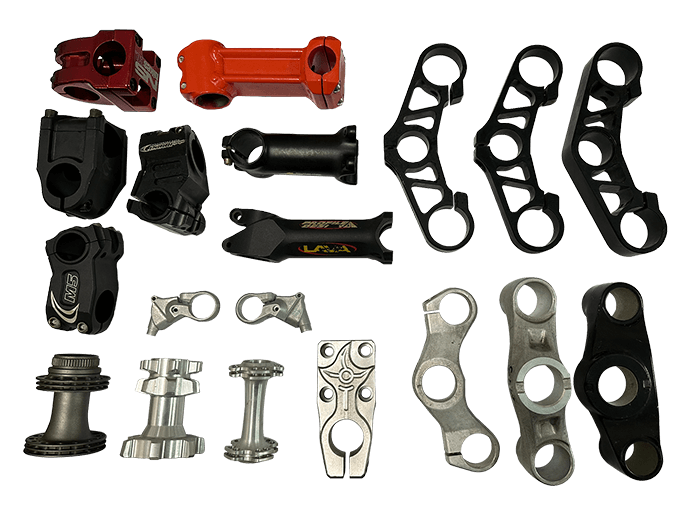

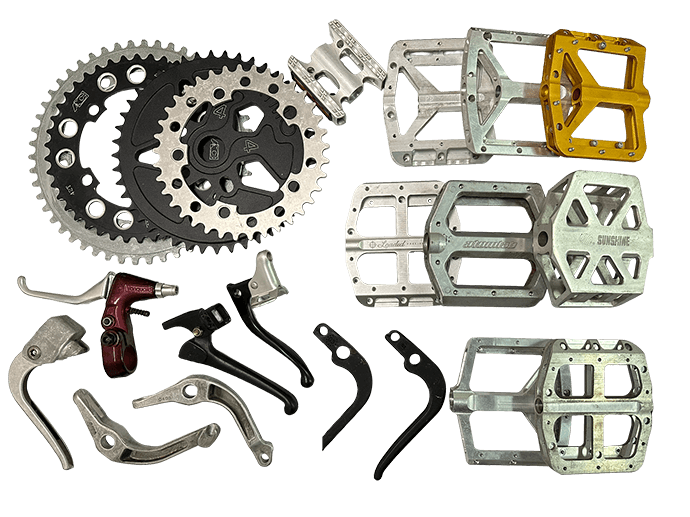

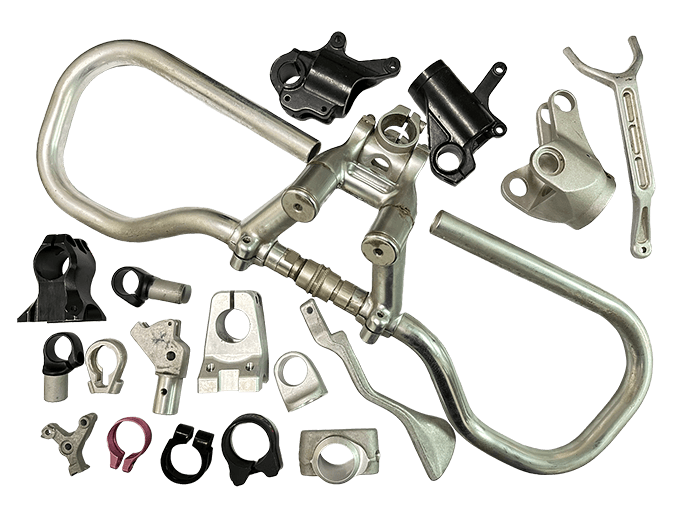

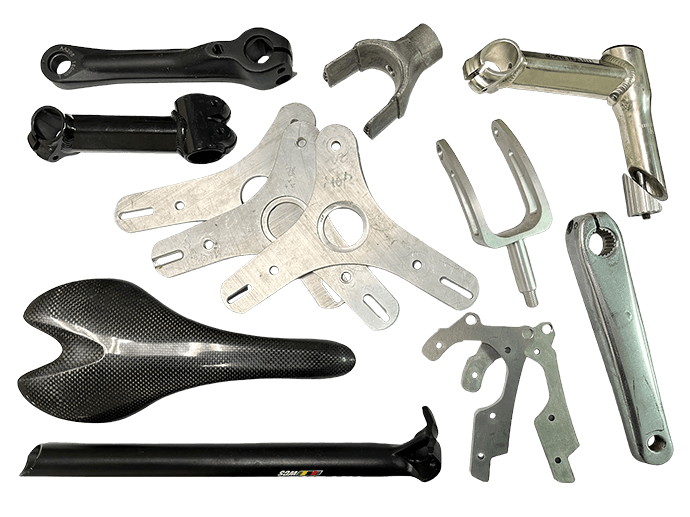

When FENG CHING was founded in 1995, it began doing OEM manufacturing of traditional aluminum alloy bicycle parts for major manufacturers. Such as forks, levers, handlebars, stems, stem caps, frames, cranks, seat posts, seat post clamps, tubes, pedal, through axle, dropout, chainwheel, brake disc, and derailleur. Bicycle component production has remained a major part of FENG CHING’s manufacturing.

With over 25 years’ experience in the manufacturing of high-precision, and high-value-added products, FENG CHING has a solid understanding of aluminum alloy parts, and has a complete range of CNC 3-axis, 4-Axis and 5-axis machines, and 90 Degree Right Angle milling machines, with the ability to produce very complex 3D parts. Multi-Axis machining results in reduced lead times and lower costs.

Besides CNC machining, FENG CHING offers after-machining processing, and surface treatment, including sand blasting finishing for high quality esthetic effects and increased product lifetime.

Your One-Stop OEM/ODM Service Provider

At FENG CHING, we are here to support your project from prototyping to production. Whether you require single-part prototyping or high-volume CNC machining, we’re fully equipped to meet your needs. If you are looking to manufacture light and sturdy CNC bike components, let FENG CHING help you speed up your CNC machining and reduce the cost of your next project.