OEM/ODM Service

Our Value

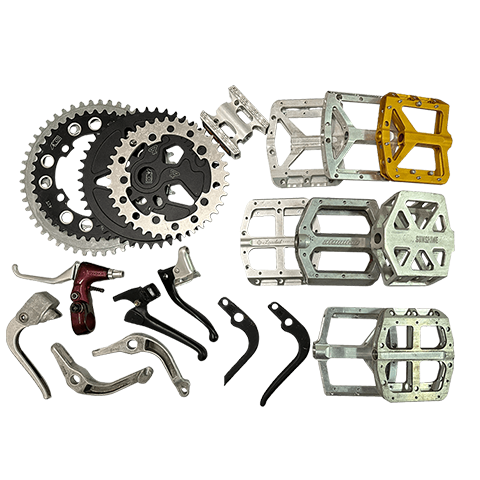

When FENG CHING was founded in 1995, we began doing OEM and ODM manufacturing of traditional aluminum alloy bicycle parts and scooter parts for major manufacturers. Our R&D department not only simply follow the drawings, but also makes suggestions for improvements to support your project from prototyping to production.

Consistently completed from Planning -> Execution -> Verification -> Action

FENG CHING Manufacturing Capabilities

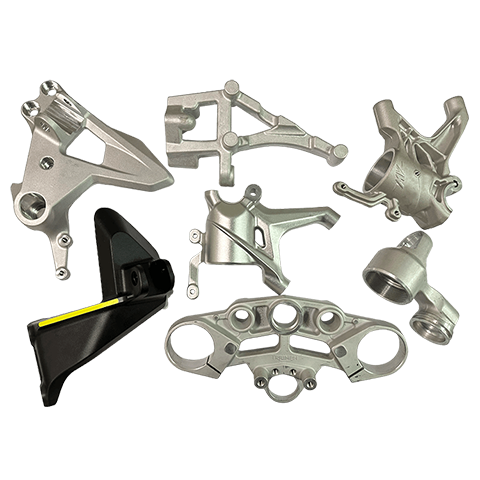

We presently manufacture OEM automotive parts used in world-class racing cars, automobiles, heavy locomotives, bicycles, hand tools and other related industries.

At present, FENG CHING has 60 CNC machines running 24 hours a day, and our CMM testing procedures ensure that quality is maintained to the highest of standards for the customer satisfaction.

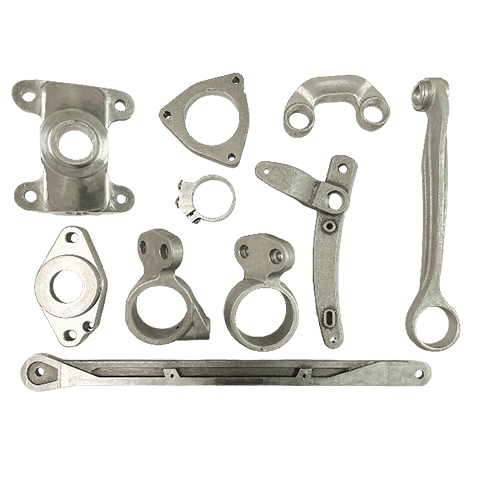

Our Processing Parts

Quality Control

Quality Assurance

We presently manufacture OEM automotive parts used in world-class racing cars, automobiles, heavy locomotives, bicycles and other related industries.

Therefore, the quality of products must be both functional and safe to satisfy customers.

Certification

Not only holding an ISO 9001: 2015 certification, FENG CHING also capable of employs extensive quality control measures including APQP, FMEA and SPC planning.