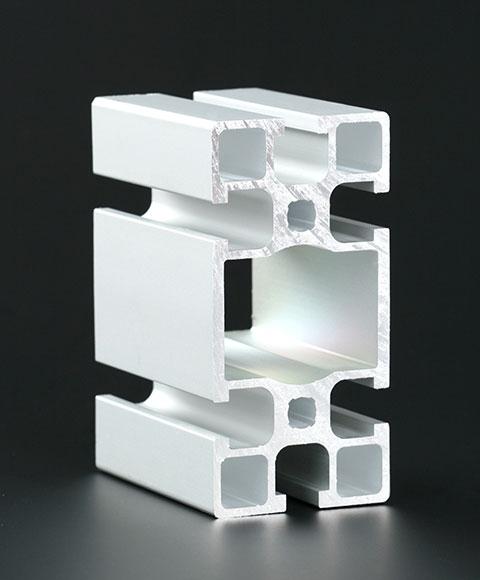

Aluminum Extrusion

Process : Solid metal → Cutting → Pre-heating → Extrusion → Straightening → Cutting → Heat Treatment

Extrusion is a hot forming method in which a metal material is continuously passed through a die with a predetermined shape at extremely high pressure and temperature, by heating, plasticizing and screw extruding, and then cooled to form the desired shape. It is typically used to produce long or continuous shape parts such as rods, tubes, strips, etc. Commonly used extruded metal materials include aluminum, copper, magnesium, titanium, lead, etc., even brittle materials can also be extruded.

Advantages : Multiple product specifications, greater production flexibility, small batch production, high dimensional accuracy, good surface quality, lower equipment cost.

Disadvantages : Large waste loss, low extrusion speed, uneven metal flow.

Applicable industries : Automotive, ships, construction, electronic industry, consumer goods, etc.